本文是一篇电气自动化论文,笔者在实践中进行理论研究时,设备的尺寸可能存在问题,冷却过程中排放的蒸汽可能会对变压器本身和整个装置造成损害,但不排除这种技术的经济成分较高的事实,模拟满足之前设定的条件,进行了冷却和温度控制。

1 Introduction

1.1 Background and significance of study

Traction substation is a device designed to convert and supply electricity to the electrictransport network.It is the specialized equipment applied by the urban railway systems.It isalso installed on all metro substations[1].The traction substation can lower the voltage to anacceptable level or convert AC to DC.Traction substation has a number of features.Its deviceis affected by the field of operation and purpose.

There are traction substations of direct and alternating current.Each group has its ownspecial technical characteristics.DC substations are designed for a load of 6-330kV.Electricalcommunications are supplied to them by air or by cable.If the transport operates from avoltage of less than 110kV,the design provides for lowering equipment.When entering thedevice,the current first decreases,and then straightens and enters the communicationnetwork.

Design of traction substations of alternating current is carried out without theparticipation of the converting unit.In this case,the design will be easier.To be able to rectifythe voltage in the network in parallel substations when connecting the same phase,specialcircuits are used.They allow the connection of transformers to be symmetrical.The mostfamous of them is the scheme of the double screw.Its application allows loading phases moreevenly,avoiding voltage losses of consumers.There are mobile and stationary substations.The second option is used more often.Mobile devices play the role of batteries.Their designhas certain difficulties.Therefore,they are used rarely[2][3].

..........................

1.2 Research status

1.2.1 Development situation of vapor-compression technology

The foundations of the design of the piston steam engine,invented in the late 18thcentury,mainly survived to the present day.At the time,the steam engine gave the technique,before people almost did not know the machine-engines,a new powerful means ofdevelopment.Currently,it is partially replaced by other types of engines.However,it has itsmerits,sometimes forcing her to choose the turbine.This is the ease of handling it,the abilityto change the speed and reverse.

Its main part is a cast-iron cylinder,in which the piston moves.Next to the cylinder is asteam distribution mechanism.It consists of a spool box having a connection to the steamboiler.In addition to the boiler,the box through the hole is communicated with the condenser(in locomotives often just through the chimney with the atmosphere)and with the cylinderthrough two Windows.In the box there is a spool,driven by a special mechanism by means oftraction so that when the piston moves to the right,the left part of the cylinder through thewindow communicates with the steam boiler,and the right—through the window with theatmosphere.Fresh steam enters the cylinder on the left,and the exhaust steam from the rightside of the cylinder goes into the atmosphere[14][15].Then,when the piston moves to the left,the spool moves so that fresh steam enters the right side of the cylinder,and the exhaust steamfrom the left side goes into the atmosphere.Steam is supplied to the cylinder not all the timethe piston stroke,but only at the beginning of it.After that,due to the special shape of thespool,the steam is cut off(ceases to be fed into the cylinder)and the work is performed byexpanding and cooling steam.The cutoff of steam gives great energy savings.Thelocomotives are usually equipped with two cylinders(sometimes more).Steam comes first inone cylinder,and then in the second.Since the steam in the first cylinder expands,thediameter of the second cylinder is much larger than the first.On locomotives,as a rule,putfire-tube boilers;there is a superheater.

.........................

2 Vapor-compression cycle(VCC)

2.1 Chapter’s outline

The fundamental of this study is the cooling system for the transformer,which in turn iscompletely based on the principle of steam-compression cycle.The cycle has beenmodernized,due to the appearance of two loops and providing them with controllers.

2.1.1 Concepts of refrigeration

The idea of cold and heat is created on the basis of our subjective impressions.Bytradition,we tend to call cold any object whose temperature is below the temperature of ourbody.In the technique under artificial cold knows as warm,take away from the body,iscolder than the external environment.By its physical nature,cold is no different from heat.The difference is only in the speed of molecules and atoms of the body.Molecular kinetictheory teaches that the molecules of the body are in continuous thermal motion.The energy ofthis movement is called warmth.All molecules in a particular body move at different speeds,but each temperature is characterized by a certain speed.The higher speed of the molecules,the higher body temperature.Therefore,the temperature expresses in conventionalunits-degrees-the degree of heating of the body and the amount of heat is a measure of theamount of energy of motion of its molecules.

For the unit of heat and cold a large calorie or kilocalory(kcal)is adopted,i.e.theamount of heat required to heat 1kg of water at 1℃(from 19.5 to 20.5℃)at normalatmospheric pressure,or the amount of heat that must be taken from 1kg of water to cool it at1℃.In the international system of units(SI)as a single measure of energy of all kindsadopted Joule(J).The calorie is an off-system unit of heat,it is equal to 4.187J.As a derivedunit adopted kilowatt-hour(kW·h)equal to 3600 kilojoules(kJ),or 860kcal,1kcal/h=1.163watts[20].

...........................

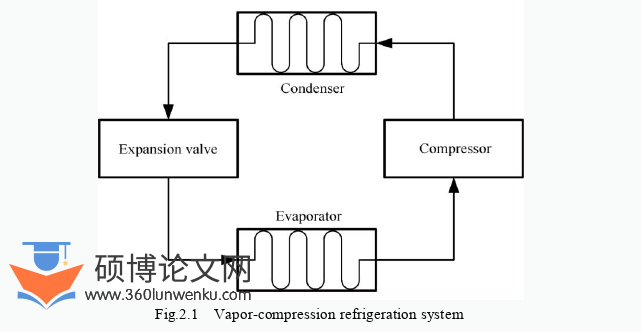

2.2 Module of VCC

In the vapor-compression refrigerating cycle(shown in Fig.2.1)to produce refrigeration,the process of boiling liquid is using for fluids or refrigerants working.Liquid refrigerant(e.g.air)from cylinder through the valve enters the coil,located in a cooled room.The heat fromthe room is transferred to the refrigerant and spent on its evaporation.At the same time,theair temperature in the room decreases.

By continuously feeding liquid refrigerant into the coil,it is possible to achievelong-term and stable cooling of the room.However,with this method of obtaining cold,therefrigerant is irretrievably lost,so in the actual refrigerating machine the vapors formedduring the boiling process are collected and again converted into liquid.This is achieved bycompressing the refrigerant vapor to a certain pressure and then cooling it.Energy is used tocompress the refrigerant,but the process of obtaining the cold becomes continuous,there isno refrigerant loss and the refrigerant cylinder is only needed for the initial filling of thesystem.

In the condenser,the vapors are first cooled,then converted into a liquid(condensed).The condensation process takes place at a constant pressure PK and temperature TK.Thecondenser is cooled by water or outside air(only air-cooled condensers are used onrefrigerated rolling stock).From the condenser,the refrigerant enters the liquid state to theexpansion valve,which with a decrease in pressure from PK to PO(boiling pressure)providesthrottling of the liquid refrigerant.During the throttling process,part of the liquid is convertedinto steam,so a mixture of liquid and wet steam enters the evaporator from the expansionvalve.The liquid refrigerant boils in the evaporator at a temperature of T0 and a pressure of P0.The refrigerant takes the heat necessary for boiling away from the cooled medium(air of thecargo compartment of the car).Thus,the same amount of refrigerant circulates in therefrigeration machine during compressor operation,changing only its aggregate state duringboiling and condensation.To ensure stable and reliable operation,the refrigerating machine isequipped with additional devices(oil separators,receivers,etc.).This machine is called arefrigeration unit.

电气自动化论文怎么写

.............................

3Inner loop..............................19

3.1 Design of inner loop module................................19

3.1.1 MPC controller.....................................19

3.1.2 Relation of MPC and VCC.......................20

4 Outer loop.................................22

4.1 Design of outer loop module............................22

4.1.1 Main component-PI controller........................................22

4.1.2 Introduction of Minimal stable superheat(MSS)........................22

5 Temperatures control of system....................................25

5.1 Concept of temperature control.............................25

5.1.1 Temperature control of transformers...................................27

5.1.2 Utilized temperature control method................................29

5 Temperatures control of system

5.1 Concept of temperature control

According to modern concepts,the temperature is a conditional statistical value directlyproportional to the average kinetic energy of the particles of matter(molecules or atoms).Theconcept of"temperature"is not applied to a single molecule.Statistical laws do not apply tothe space with rarefied matter.The temperature in this case is determined by the power of theradiant energy flowing through the body.The concept of"temperature"is expanding with thedevelopment of science and technology.In particular,the concept of"electronic temperature"is used in the study of high-temperature plasma.

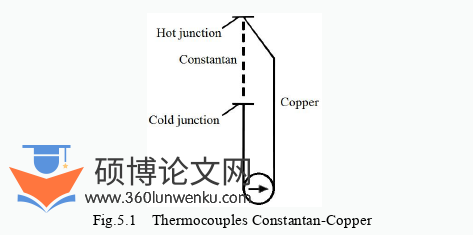

For reliable operation of the equipment is of great importance,thermal regime andviolation of this regime can lead to a decrease in service life.It is necessary to systematicallymonitor the temperatures and temperature exceedances of the most critical elements.Considerwhat devices,and these devices allow you to measure both local and average temperaturesand temperature exceedances.

Measuring with thermometers is one of the easiest methods.Built-in stationarythermometers are used to control the temperature of the bearing oil,air and gas in electricmachines,the oil temperature in transformers.Preference is given to alcohol thermometersover mercury,because in the latter,additional heating of mercury by eddy currents frommagnetic scattering flows is possible.

电气自动化论文参考

................................

Conclusion

The method described above is innovative by utilizing energy efficient scheme in termsof combining two non-compatible systems:vapor-compression system and dry-typetransformer.It provides optimal energy use by compressor,and the temperature sensorprovides information about the increase of temperature,thereby activating the operation ofcompressor.The simulation was carried out on the MATLAB platform,which give results,after making all the parameters and data combing,it was found that the cooling by thismethod of the core and the winding of the transformer is possible.

Work has been carried out as follow:

(1)Determination of the main component of the research-the choice of the controlstructure.(2)Installation of controllers and set of parameters to loops.(3)R134A as refrigerant for the compressor and the amount of it.(4)Determination of the minimum and maximum temperature for the VCC system.(5)Selection of the most optimal temperature sensor.(6)Modeling in MATLAB,construction of the scheme.(7)Taking results which similar to the real ones.

reference(omitted)